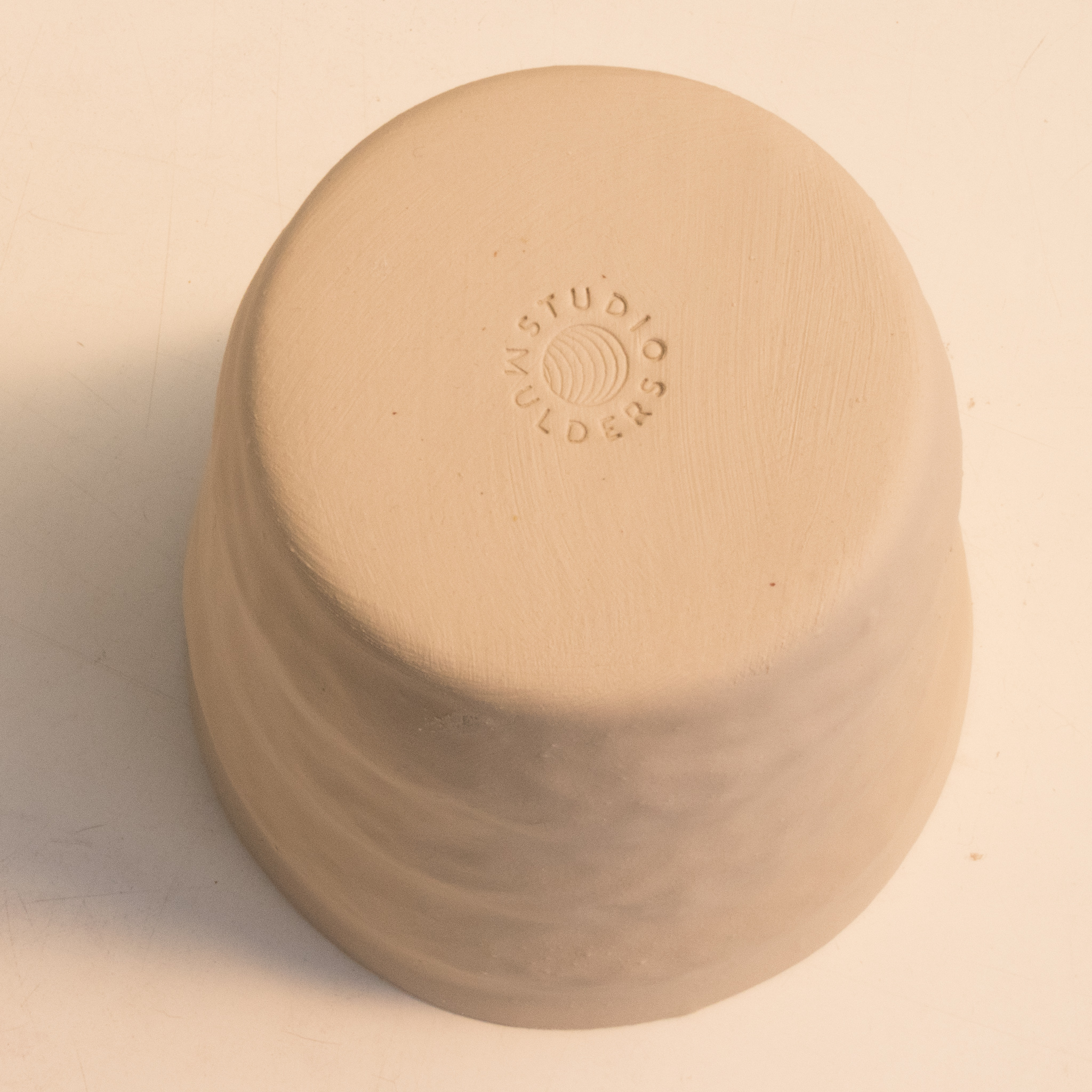

About my handmade process

I design forms in clay and use fine plaster to make moulds from them. Alternatively I use discarded plaster moulds to make new forms trough cutting and reassembly. My porcelain and stoneware slips are chosen for their warm cream like colour once fired. The stoneware is slightly more grey and used for teapots and mugs, ideal to add hand built pieces like handles or feet.

After the slip cast pieces are released from the plaster mould, they are trimmed, dried and cleaned up ready for the first bisque firing to 1000C. The bisque firing is essential for a good application of the glazes as the cups are thin and fragile until they are fired to vitrification in the second firing to 1270C. At this temperature the clay and glazes melt together forming the ceramics. In a final step I sand the cups and make their bottoms smooth to touch.

About my glazing

I mix all glazes from raw materials like feldspar, kaolin and silica. Each product has a combination of up to as many as four different glazes. One by one each glaze is applied carefully such that, when fired, they cascade and flow over the clay surface - but not too much! Very important as glaze running over the bottom of the cup ruins the ceramics.

The glazes are designed intentionally to amplify small variations in the surface texture, the application process, the firing cycle and the location in the kiln. The ever-changing variations that arise are reminiscent of many processes of nature, wether it be the waves in the ocean, the leaves on a tree, the scrubs in the outback, or the clouds in the sky.

Each of these are similar to each other, yet none are the same.

Each product in the online shop is photographed individually and the product you buy is exactly as it is on the photo in the shop.

The images below show examples of the JAZZ travel cups in four different glaze palettes.